Discover high-performance FRP Grating solutions designed for industrial, commercial, and infrastructure projects. We offer a wide range of molded and pultruded FRP grating options to meet your specific needs.

Explore our comprehensive range of high-performance FRP Grating, including molded and pultruded options. We provide durable, corrosion-resistant FRP Grating solutions tailored for industrial, commercial, and infrastructure applications, ensuring safety and longevity.

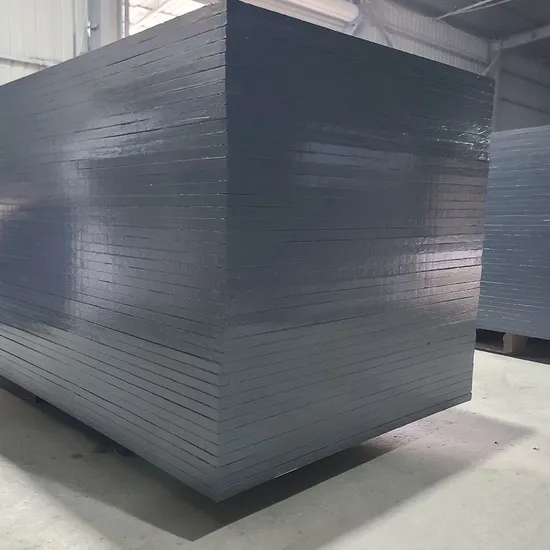

Engineered for harsh environments, this molded fiberglass grating provides a durable, anti-slip, and corrosion-proof solution for industrial walkways and platforms.

Read More

Engineered molded fiberglass grating offering superior slip resistance and durability for a wide range of industrial applications and corrosive environments.

Read More

Engineered with continuous glass fibers and resin for superior strength and corrosion resistance in industrial flooring.

Read More

Engineered composite FRP grating providing a durable, lightweight, and corrosion-resistant flooring solution for industrial environments.

Read MoreWe provide tailored FRP Grating solutions to meet diverse project requirements, from heavy-duty industrial applications to specialized commercial needs. Explore our range:

Ideal for high-strength, unidirectional load-bearing applications. Our pultruded FRP grating offers superior stiffness and corrosion resistance.

Provides excellent bi-directional strength and versatility. Suitable for walkways, platforms, and trench covers in various industries.

Choose from a variety of resin systems, including polyester, vinyl ester, and phenolic, to match your specific environmental and performance requirements. Ideal for specialized FRP Grating needs.

We adhere to strict quality control throughout our manufacturing process, ensuring consistent performance and durability of our FRP Grating products.

We use only high-quality resins, including polyester, vinyl ester, and phenolic, to ensure superior corrosion resistance and long-term performance of our FRP grating.

Our FRP grating is reinforced with high-strength fiberglass, providing exceptional load-bearing capacity and structural integrity.

We implement comprehensive quality checks at every stage, from raw material inspection to final product testing, to guarantee the highest standards for our FRP Grating.

Our modern facility is equipped with advanced technology to ensure efficient and precise production of high-quality FRP Grating.

Dedicated pultrusion lines for high-volume production of pultruded FRP grating profiles.

Large-capacity molding presses for producing various sizes and configurations of molded FRP grating.

Controlled environment for precise resin mixing and preparation, ensuring consistent material properties.

Fully equipped laboratory for comprehensive testing and quality assurance of our FRP Grating products.

Our streamlined production processes and large-scale capacity enable us to meet the demands of large industrial and commercial projects.

Automated pultrusion lines ensure consistent quality and high throughput for pultruded FRP grating.

Optimized molding processes for efficient production of molded FRP grating with minimal waste.

Robust inventory management system to ensure timely delivery of standard and custom FRP grating products.

We are a leading provider of FRP Grating solutions, offering superior quality, expertise, and customer service.

Our team has extensive experience in FRP Grating design, manufacturing, and application, providing expert guidance for your projects.

We use premium materials and adhere to strict quality control standards to ensure the long-term performance and durability of our FRP Grating.

We offer a wide range of customization options, including resin type, size, color, and surface texture, to meet your specific FRP Grating requirements.

Our dedicated customer support team is available to assist you with technical inquiries, order processing, and project support for all FRP grating solutions.

We are a dedicated manufacturer and supplier of high-performance FRP Grating solutions for a wide range of industries.

Founded in 2010, we have consistently focused on providing high-quality FRP Grating solutions and exceptional customer service to industrial and commercial clients.

We maintain strict quality control standards throughout our production process, ensuring that our FRP grating meets or exceeds industry standards.

Our commitment to innovation and customer satisfaction has earned us a reputation as a trusted partner for FRP Grating projects.

Customer-centric approach with 24/7 support for FRP Grating inquiries.

Industry-leading FRP Grating product quality and innovation.

Sustainable and eco-friendly manufacturing practices.

Comprehensive after-sales service and technical support.

Find answers to common questions about our FRP Grating products and services.

Hear from satisfied customers about their experiences with our FRP Grating products and services.

We've been using their FRP Grating for several years in our chemical processing plants. The corrosion resistance and durability are exceptional, significantly reducing our maintenance costs.

Henry Gabriel Martinez

Procurement Manager, PetroChem Industries

Their FRP Grating was the perfect solution for our wastewater treatment facility. It's lightweight, easy to install, and withstands the harsh environment perfectly. We are very happy with the wholesale prices.

Lisa Wang

Project Engineer, WaterWorks Solutions

We rely on their FRP Grating for our docks and marine platforms. The non-slip surface and resistance to saltwater corrosion provide a safe and durable solution for our operations. Great quality industrial FRP grating!

Alexander Henry Adams

Operations Director, Coastal Marine

Have questions about FRP Grating or need a custom quote? Our team is ready to assist you with your project needs.

Huli Industrial Park, Huli District, Xiamen, Fujian, China

+1234567890

Monday - Friday: 9:00 - 18:00

We're here to help you with your needs. Let's talk about how we can help you.